Background

Background

With the deepening of enterprise intelligent manufacturing, the basic network is responsible for the overall data transmission of various business systems in the entire enterprise park. The IT resource platform carries multiple internal and external businesses of the enterprise. Once a problem occurs, it will have an immeasurable impact on the information management and production of enterprises, especially in the enterprise park, where there are core functional modules such as production research and development, logistics procurement, sales management, and quality control. The problem of enterprises regressing from information management to paper management due to unreasonable construction of the basic platform is everywhere. It is crucial to analyze the technical characteristics of each business in the actual use process, take the current business system and future business development needs as the core, take user service quality as the foundation, and consider the management and operation experience of the information department managers to design a stable, reliable, easy-to-use and easy-to-manage park network. Reducing costs and improving efficiency are the inevitable demands of the development of enterprise intelligent manufacturing and informatization. Therefore, the construction of the enterprise park network must consider how to help the construction of intelligent manufacturing and future expansion. Flexibility, high stability, intelligence, universal connection, and intelligent management will be the inevitable choices for enterprise park network design.

Solutions

Solutions

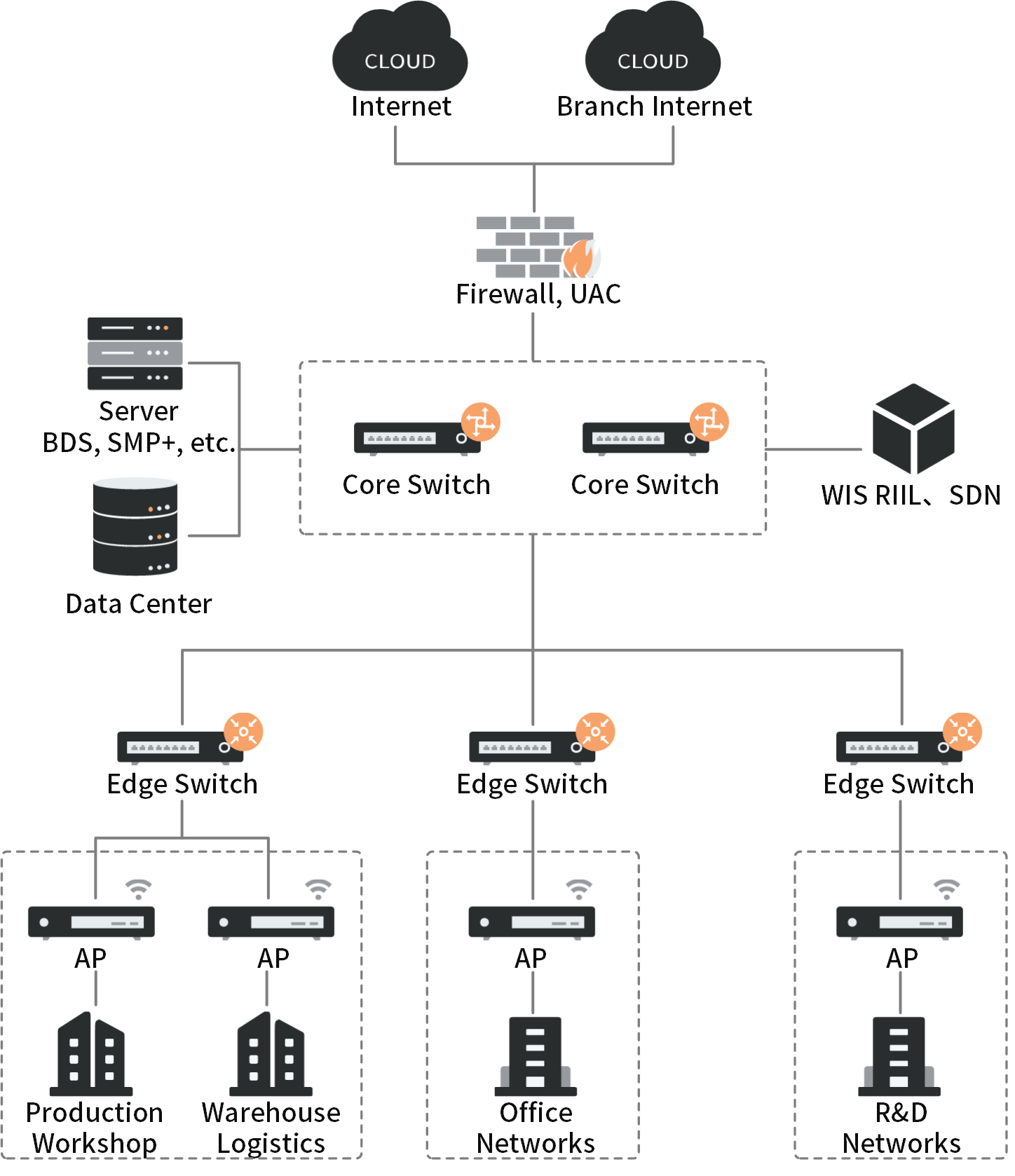

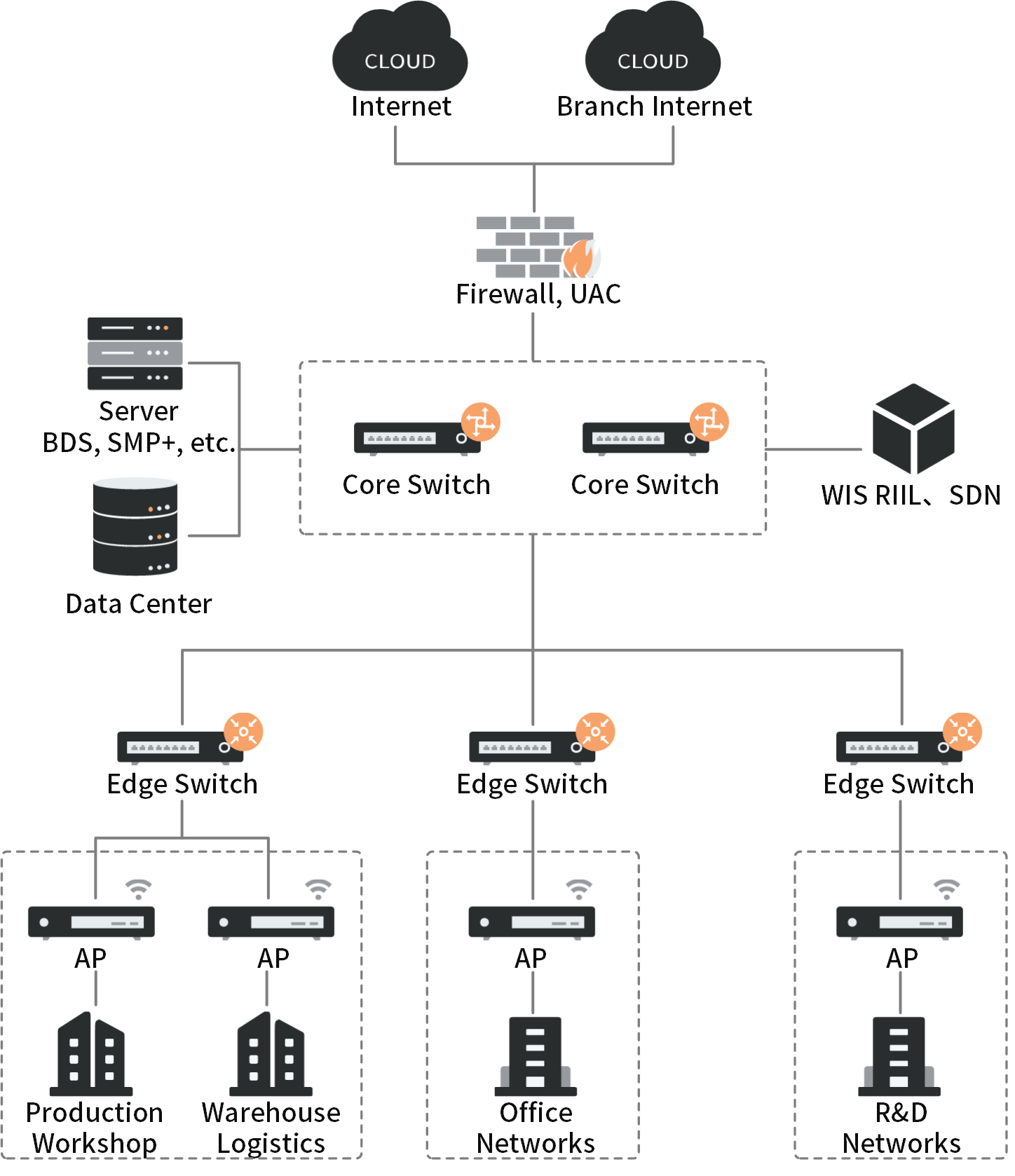

The overall network of the enterprise park is divided into data centers, production, offices, R&D, equipment networks, exports, and other areas, each of which performs its duties to ensure network robustness and scalability. Through Wi-Fi 6, industrial wireless zero roaming coverage, 5G technology, SDN and SDN security defense technology, and RIIL integrated operation and maintenance, the entire park becomes seamlessly connected, intelligent and secure, and simple to operate and maintain. G3S realizes the rapid superposition, rapid deployment, and emergency expansion of various services. At the same time, through the deployment of SDN, industrial wireless zero roaming, and RIIL integrated operation and maintenance systems, the efficiency of enterprises in business expansion, industrial data acquisition, operation and maintenance detection, etc. has been greatly improved. G3S reduces the time for new business launches and troubleshooting, and greatly saves costs.

Introduction

Introduction

Background

Background Solutions

Solutions

Advantages

Advantages